PVC Laminated Fabrics Industry Knowledge Extension

What are the key applications and benefits of PVC Laminated Fabrics, and how do they contribute to durability, versatility, and performance in various industries?

PVC Laminated Fabrics are widely used in a range of industries for their exceptional durability, versatility, and performance. These fabrics consist of a PVC layer that is bonded to a base fabric, resulting in a strong and resilient material. Let's explore the key applications and benefits of PVC Laminated Fabrics and how they enhance performance in various industries.

What are the primary applications of PVC Laminated Fabrics?

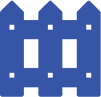

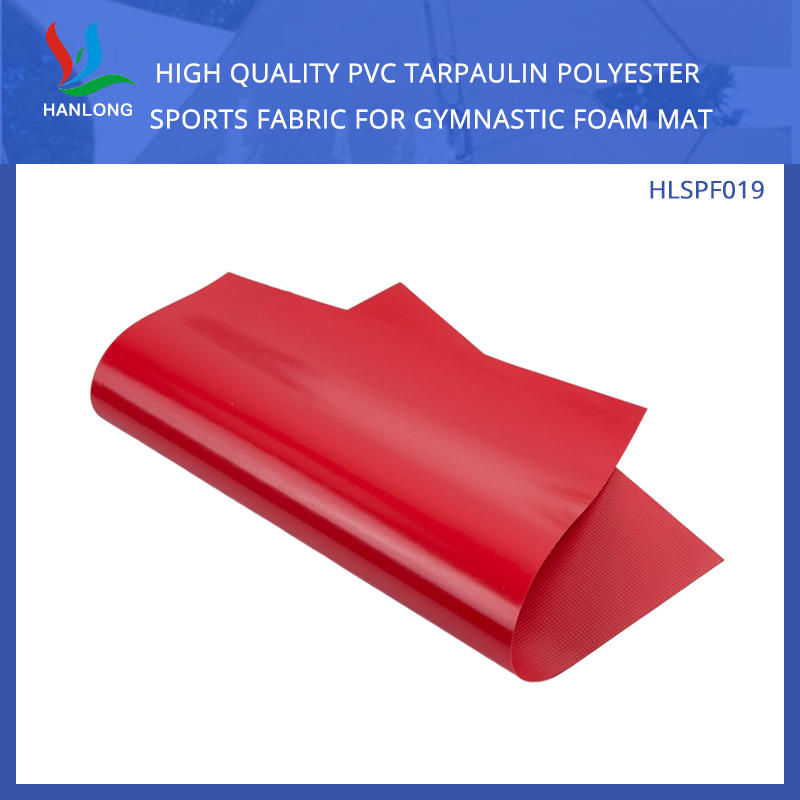

PVC Laminated Fabrics find application in perse industries due to their versatility and durability. They are commonly used in the manufacturing of truck covers, awnings, tents, banners, inflatables, and protective covers. PVC Laminated Fabrics are also utilized in sectors such as agriculture, construction, transportation, and sports. Their ability to withstand harsh weather conditions, UV exposure, and wear and tear makes them suitable for both indoor and outdoor applications.

How does the lamination process contribute to the durability of PVC Laminated Fabrics?

The lamination process is a critical step in the manufacturing of PVC Laminated Fabrics. It involves bonding the PVC layer to the base fabric using heat and pressure, creating a strong and durable composite material. This lamination process enhances the fabric's resistance to tearing, punctures, and abrasion, making it highly durable and long-lasting. The PVC layer also provides excellent protection against UV radiation, preventing color fading and degradation over time.

What are the benefits of PVC Laminated Fabrics in terms of waterproofing and weather resistance?

PVC Laminated Fabrics offer exceptional waterproofing properties, making them ideal for applications where protection against moisture is crucial. The PVC layer acts as a barrier, preventing water penetration and ensuring that the fabric remains dry and resistant to mold and mildew. Additionally, PVC Laminated Fabrics exhibit excellent weather resistance, withstanding exposure to extreme temperatures, sunlight, and harsh environmental conditions. This resistance to weathering contributes to their longevity and reliability in outdoor applications.

How does the versatility of PVC Laminated Fabrics benefit different industries?

The versatility of PVC Laminated Fabrics makes them a preferred choice for a wide range of industries. These fabrics can be customized in terms of thickness, colors, patterns, and textures, allowing for a broad spectrum of design options. PVC Laminated Fabrics can be tailored to meet specific requirements, ensuring they align with the aesthetic and functional needs of different applications. Whether it's creating vibrant banners, sturdy truck covers, or weather-resistant tents, the versatility of PVC Laminated Fabrics enables their adaptation to various industry demands.

What are the performance advantages of PVC Laminated Fabrics in terms of strength and flexibility?

PVC Laminated Fabrics offer a unique combination of strength and flexibility, making them highly suitable for demanding applications. The base fabric provides structural strength, while the PVC layer adds reinforcement and protection. This combination results in a fabric that can withstand heavy loads, tension, and stretching without compromising its integrity. PVC Laminated Fabrics exhibit excellent dimensional stability, ensuring they retain their shape and structure even under prolonged use. The flexibility of these fabrics also allows for ease of handling, folding, and installation, facilitating their use in various industries.

In summary, PVC Laminated Fabrics are versatile and durable materials that find application across multiple industries. Their ability to withstand challenging environmental conditions, provide waterproofing, and offer strength and flexibility makes them a preferred choice for truck covers, awnings, tents, banners, and more.

How does the lamination process enhance the performance and durability of PVC Laminated Fabrics, making them suitable for a wide range of applications in various industries?

The lamination process is a crucial step in the manufacturing of PVC Laminated Fabrics, contributing significantly to their performance and durability. By understanding the benefits of lamination, we can appreciate why PVC Laminated Fabrics are widely used in numerous industries. Let's explore how the lamination process enhances the performance and durability of PVC Laminated Fabrics.

What is the lamination process for PVC Laminated Fabrics?

The lamination process involves bonding a layer of PVC (Polyvinyl Chloride) to a base fabric using heat and pressure. The base fabric can be made of polyester, nylon, or other synthetic materials. During lamination, the PVC layer is applied to one or both sides of the fabric, creating a strong and resilient composite material.

How does lamination contribute to the durability of PVC Laminated Fabrics?

The lamination process significantly enhances the durability of PVC Laminated Fabrics. The PVC layer acts as a protective barrier, shielding the base fabric from external factors that can cause damage. The PVC layer provides excellent resistance to abrasion, punctures, tears, and UV radiation. This added layer of protection ensures that PVC Laminated Fabrics can withstand harsh environmental conditions, heavy use, and prolonged exposure to sunlight without compromising their integrity.

What are the performance advantages of PVC Laminated Fabrics?

PVC Laminated Fabrics offer several performance advantages due to the lamination process:

a) Waterproofing: The lamination process creates a tight bond between the PVC layer and the base fabric, resulting in excellent waterproofing properties. This makes PVC Laminated Fabrics highly suitable for applications where protection against moisture is crucial, such as truck covers, outdoor signage, and protective covers.

b) Weather resistance: PVC Laminated Fabrics exhibit remarkable resistance to extreme weather conditions. They can withstand temperature variations, heavy rain, snow, and sunlight exposure without deteriorating or losing their structural integrity. This weather resistance makes PVC Laminated Fabrics reliable for outdoor applications in industries such as construction, agriculture, and transportation.

c) Chemical resistance: The PVC layer in PVC Laminated Fabrics provides resistance to various chemicals, including oils, solvents, and mild acids. This chemical resistance makes them suitable for industrial applications where exposure to potentially corrosive substances is common.

d) Flame retardancy: PVC Laminated Fabrics can be manufactured with flame retardant properties, offering added safety in applications where fire resistance is essential, such as tents, awnings, and partitions.

How does lamination enhance the versatility of PVC Laminated Fabrics?

The lamination process enhances the versatility of PVC Laminated Fabrics in multiple ways:

a) Customization: PVC Laminated Fabrics can be customized in terms of color, pattern, texture, and thickness to meet specific design and functional requirements. This allows for a wide range of aesthetic options and the ability to match the fabric with different applications and branding needs.

b) Design flexibility: The lamination process enables the creation of PVC Laminated Fabrics with various properties, such as translucency or opacity, matte or glossy finishes, and different levels of flexibility. This versatility makes PVC Laminated Fabrics adaptable to different industry demands, whether it's for flexible doors, advertising banners, or outdoor structures.

c) Printing capabilities: The smooth and consistent surface of PVC Laminated Fabrics allows for high-quality printing, making them ideal for applications that require vibrant graphics, logos, or branding elements.

How does the lamination process contribute to ease of maintenance?

PVC Laminated Fabrics are relatively easy to clean and maintain due to the lamination process. The PVC layer provides a smooth surface that is resistant to dirt, stains, and mildew. This makes PVC Laminated Fabrics easy to wipe clean with water and mild detergent, ensuring their longevity and aesthetics.

In conclusion, the lamination process plays a vital role in enhancing the performance and durability of PVC Laminated Fabrics. By providing waterproofing, weather resistance, chemical resistance, and flame retardancy, PVC Laminated Fabrics can withstand the demands of various industries. The lamination process also contributes to the versatility and ease of maintenance of these fabrics, making them suitable for a wide range of applications.

English

English 中文简体

中文简体

Home

Home